By some estimates, the world industrial coatings market will be worth in excess of $119 billion within the next five years. Coatings – resins, metals, composites, and other synthetic coverings – are advancing at a rapid clip thanks to demand from dozens of sectors including automotive, protective, aerospace, and even energy.

Noah Chemicals works with manufacturers to supply high-purity industrial chemicals for use in coatings all over the U.S.A. Here are three advancements in the coatings space our chemists are keeping a close eye on.

Safer Alternative to BPA

BPA, or bisphenol A, is in the process of being phased out as a commonplace industrial chemical. Although technically considered “safe” for use in many countries, BPA is suspected to cause endocrine and hormone disruption in humans. Scientists are getting closer to finding viable substitutes for BPA compounds, including one made from only limonene and CO2. Limonene, a compound derived from citrus fruit, is an incredibly eco-friendly ingredient and can actually be used to create a polymer with the highest glass transition temperature ever recorded for a polycarbonate. Relatedly, scientists at the Baylor College of Medicine have recently announced a superior method for testing BPA alternatives that produces lightning-fast results.

Self-Healing Polymeric Coatings

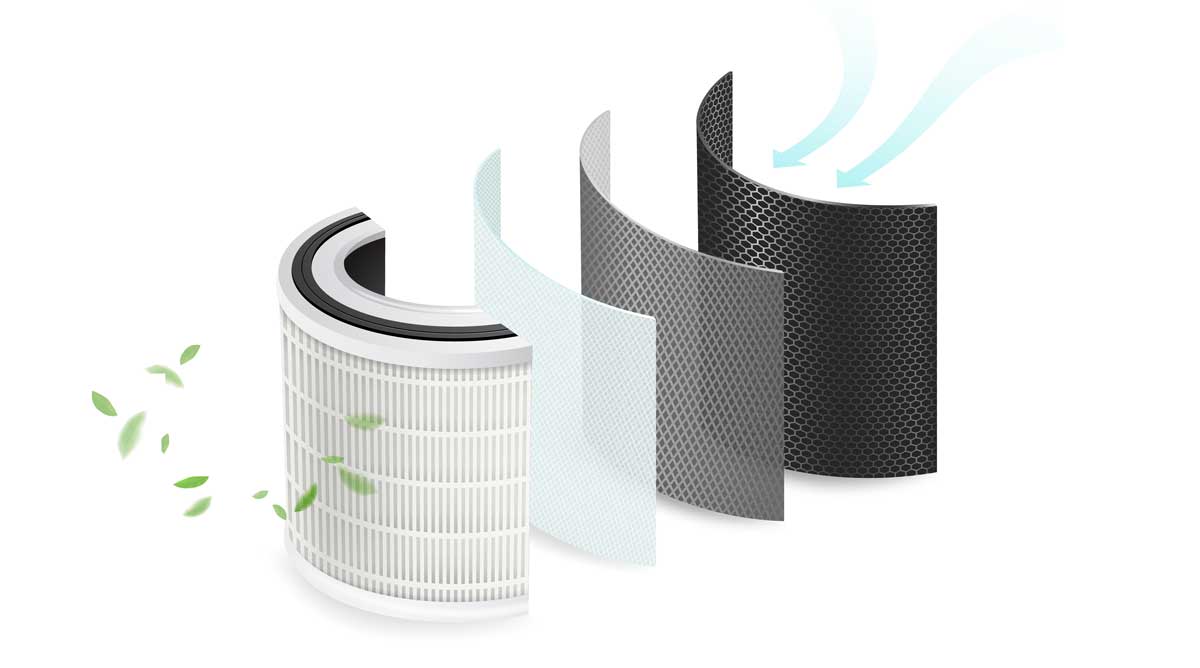

The study of self-healing compounds is a fascinating one. Commonly seen in medical applications, self-healing coatings actually hold great promise for industrial applications as well, particularly in fields where heavy use and high friction necessitates frequent mechanical maintenance. A team from the University of Illinois at Urbana-Champaign is in the process of developing a coating that’s engineered like skin, with both a “dermis-like” vascular level and an “epidermis” protective layer. When the upper-layer is damaged, UV-curable fluid can be delivered to the underlying system using pressure response valves, effectively “healing” the damage from within. It’s yet another exciting development for engineered coatings that have many practical uses in an industrial capacity.

Superhydrophobic Coatings

Hydrophobic coatings are those designed to shed water; superhydrophobic coatings utilize a nanoscopic surface layer to completely repel water. Common bases for superhydrophobic coatings (usually applied as sprays) include manganese oxide polystyrene, precipitated calcium carbonate, and most promisingly, silica nano-coating. Although super-coatings have been around for years, limitations such as cloudiness and complicated preparation have hindered widespread adoption at an industrial level. Scientists are currently working on breakthroughs including a mechanically-durable superhydrophobic coating fortified with lauric acid and silica-based nanoparticles that can be used to form a self-cleaning superhydrophobic coating. In industries where moisture matters, these coatings could potentially be game-changers.

Noah Chemicals is more than just an industrial chemicals provider – we’re a solutions company. We work with researchers and manufacturers all over the country to think outside the box; our chemicals are used support some of the most exciting industrial advancements in decades, and we take that responsibility seriously.

Need to place an order? Browse our products list here.