INSIGHTS: CHEMICAL SPOTLIGHT

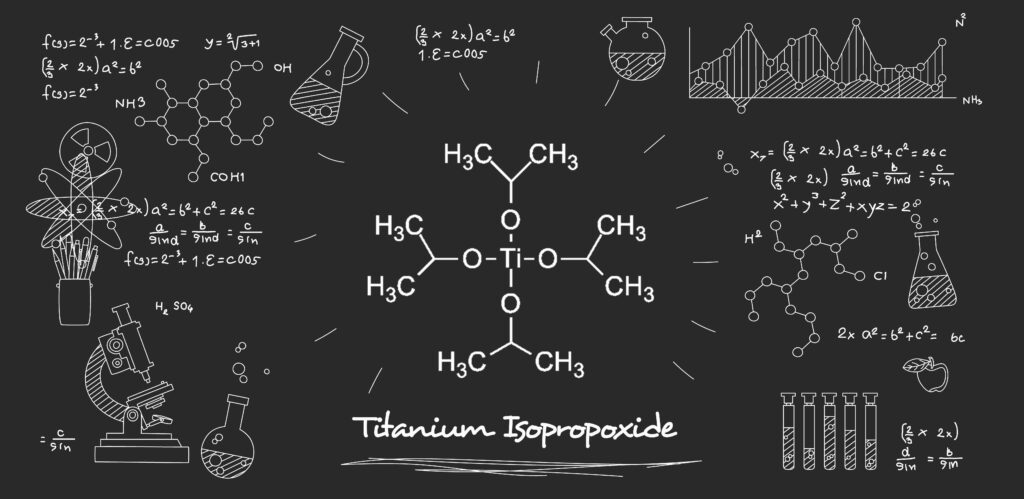

Titanium Isopropoxide

INSIGHTS: CHEMICAL SPOTLIGHT

Titanium Isopropoxide

Insights > Chemical Spotlight: Titanium Isopropoxide

Insights Overview

Industry

Ceramics, Coatings, Polymers (Chemical/Industrial Manufacturing)

Challenge

The synthesis, transport, and use of titanium isopropoxide requires careful handling due to its flammability and sensitivity to moisture and air, creating a significant challenge in maintaining safety and product integrity throughout each phase of its lifecycle.

Solution

The use of specialized containers and transport methods, coupled with controlled environmental conditions, can mitigate the risk of contamination, and ensure the highest quality titanium isopropoxide.

Outcome

Through meticulous supply chain management, the potential of titanium isopropoxide can be fully realized, leading to enhanced product quality in various industries.

Summary

Titanium isopropoxide, often abbreviated TTIP, is a crucial compound used in many modern industrial processes that rely on organic synthesis and materials science. More specifically, TTIP is frequently used in the asymmetric Sharpless epoxidation reaction of allylic alcohols, and as a catalyst in the Kulinkovich reaction for the synthesis of cyclopropanes. Most commonly, the compound serves as a precursor for the production of titanium dioxide (TiO2), a substance found in a multitude of applications from paint to sunscreen. However, the compound’s flammability and sensitivity to moisture and air presents challenges for its storage and transport. With the use of appropriate packaging and transport solutions, as well as meticulous environmental control, it’s possible to overcome this challenge.

Background

Titanium isopropoxide has a rich history in the realm of chemical synthesis. First discovered in the 1950s, it quickly became an essential tool due to its unique chemical properties. As an alkoxide of titanium, TTIP is an organometallic compound, meaning it is part of a class of compounds that contain a metal directly bonded to an organic molecule, which gives them unique properties.

TTIP is often used in a process known as sol-gel synthesis. In this method, a solution (sol) is gradually transitioned to a solid (gel) form. Titanium isopropoxide used in this process because it can be easily hydrolyzed (reacted with moisture/water) and condensed to first form a colloidal structure and upon further condensation, a connected porous network of titanium dioxide. This gel can be further aged and dried through supercritical (aerogel), thermal (xerogel) or freeze drying (cryogel) to form a solid powder end product with multiple levels of structure, functionality, and porosity.

Moreover, the compound is instrumental in metal-organic chemical vapor deposition (MOCVD). In this process, a volatile precursor like titanium isopropoxide is used to produce high-quality, thin film materials with atomic level precision control of thickness with uniformity and high repeatability. These materials are then used in a variety of applications, from microelectronics to solar cells.

While the value of titanium isopropoxide is well-established, its flammability and sensitivity to moisture and air while beneficial in the sol-gel or MOCVD processes poses significant handling challenges. It is essential that its transport and storage be carefully controlled to avoid inherent hazards and also contamination and degradation. In response to these challenges, the industry has developed specialized handling equipment and stringent environmental control measures to maintain the safety and integrity of this important chemical precursor.

The evolution of titanium isopropoxide reflects the wider trends in the chemical industry: the constant pursuit of better and safer synthetic methods, the adaptation to increasingly stringent environmental standards, and the development of cutting-edge applications in high-tech industries.

Through its versatile applications, titanium isopropoxide is significantly contributing to enhancing chemical synthesis, material science, and sustainability in economic and environmental efforts."

Chief Chemist

Evaluation

The production and use of titanium isopropoxide requires precision, expertise, and adherence to strict safety guidelines. The primary method of synthesis involves the reaction of titanium tetrachloride with isopropanol. This reaction is exothermic and produces corrosive coproducts such as hydrogen chloride and must be controlled carefully to prevent overheating and associated ignition and corrosion risks.

Titanium isopropoxide is a colorless to slightly yellow liquid that is typically stored under an inert atmosphere, such as nitrogen or argon, to prevent degradation. Moreover, it is often supplied in amber glass or metal containers, which protect against chemical and photochemical degradation. Special handling equipment is necessary to exclude any contact with air or moisture causing premature hydrolysis of the compound.

Titanium isopropoxide’s wide-ranging applications span several industries. Its primary use lies within the domain of material science, where it is utilized in the creation of ceramics, glasses, and other materials. It’s use to prepare porous titanosilicates, has been utilized to form ion exchange media to treat nuclear wastes in the removal of soluble forms of cesium-137 (137Cs). In the chemical industry, it serves as a catalyst or a precursor to other catalysts in processes like the Sharpless epoxidation, a process used to synthesize 2,3-epoxyalcohols from primary and secondary allylic alcohols. The pharmaceutical industry also harnesses the catalytic properties of titanium isopropoxide for certain types of organic reactions, such as transesterification, condensation, addition reactions and polymerization.

Ultimately, the production and use of titanium isopropoxide is a complex process that demands a high degree of precision, safety, and quality control. Through continuous research and innovation, methods are continually being refined to enhance the efficiency, increase yield, eliminate unwanted byproducts and safety of these processes by reduction of toxicity when used to replace traditional catalysts.

Conclusion

Through meticulous manufacturing and careful handling, titanium isopropoxide provides immense benefits across multiple industries. This precision results in superior quality titanium isopropoxide used in various practical and high technology applications, leading to enhanced product performance. It’s versatility in industry is apparent in adhesives, coatings, agriculture, plastics, elastomers and silicones.

Work with Us

Begin your partnership with Noah Chemicals and our expertise

to work at solving your most complex challenges.